Products and Materials Guide

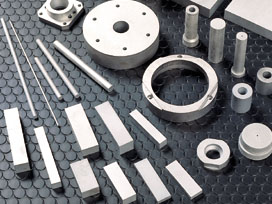

Products Guide

Materials Guide

We introduce simply concerning the various alloys which we have produced.

Tungsten Carbides

Tungsten carbide(WC) and Cobalt(Co) are main chemical compositions of Tungsten Carbide. Tungsten Carbide have marvelous friction-resistant and shock-resistant features.

We Silver Alloy have been working with material development and quality control. We have various high quality material grade of tungsten carbide. So, our customers can put the right one in the right place.

We keep up with customers short delivery request. Our Preforms make your processing time shorter, make your cost reduce.

We have various grade of Tungsten Carbide. Everything have been kept high quality. For example, R series(*1) and WS type are corrosion-resistant Tungsten Carbide. That resist chemical corrosion and elextrolytic-corrosion in wire-cutting. R serise has excellent mold release and toughness is improved, resulting 2 - 10 times longer tooling life(actual result).

SH type (Super Hard Tungsten Carbide) is our original Super-hard, Corrosion-resistant and Oxidation-resistant alloy. We have been done constant efforts for feature improvement, SH type is made remarkable progress in their strength. As a result, SH type are 7 - 10 times longer tooling life than as usual. SH type is used in many ways.

Nonmagnetic/Corrosion-resistant Tungsten Carbide

Tungsten Carbide usually have magnetizing charactristics even small, and this made it difficult to press magnet material and cut magnetic tape. We eliminated completely this charactristic by eliminating the magnetism. This type if carbide has different chemical composition from ordinally carbides, and carbides blended with this component resist to salt and chemicals and have good anti-acid charactristics at high and low temperatures. For the detail of them, please see our material table.

Cermet / Titamet

Cermet is an alloy based on Titanium Carbide(TiC). Lightweight, high strength under high temperatures and good at oxidizability. Small in affinity with iron, and capable of obtaining high wear resistance and beautiful finish surfaces in steel cutting.

Electrodes for EDM (Cu-W, Ag-W, pure Cu, Carbon)

Together with shortened delivery of molds, there has arisen a demand for shorter delivery or prompt delivery of electrodes for EDMing. We have developed and prepared and abundance of stock of high performance copper-tungsten(Cu-W) and silver-tungsten(Ag-W) according to user's desire. We are also ready for manufacture of pipe shaped products departing from specifications in 3 - 5 days. Further, we are provided with every size of stock of pure-copper(Cu) and carbon(C) electrode even for steel. Please make full use of them.

Electrodes for EDM tapping (Cu-W, Ag-W)

When tapping is made on tungsten carbide by EDMing, electrodes of copper tungsten or silver tungsten are necessary. We have inventory of such electrodes already tapped. Custom made tapped electrodes can be produced in 3 - 4 days.

Heavy Metal

Heavy metals are metals even heavier than tungsten carbide that is very heavy (maximum specific gravity:15g/cm3).

Heavy Metals are used for balance weight of precision machines and rotation inertial body or for vibration weight of self-winding clock and portable telephones. Heavy metals are very heavy as much as specific gravities of 18 or more, excellent in radiation abosorptivity, lending themselves to alot of applications.

Custom made heavy metals of different densities from users' desires are also available. CV18 is particularly resistant to corrosion. Heavy metals whose main material is metal tungsten are low in hardness, allowing an easy cutting and drilling.

Super Heat Resisting Alloy(MV type)

Metal tungsten is high melting temperature metal yet having a high thermal conductivity. Adding some other metal for heat resistance to this tungsten further enhances the heat resisting property.

Taking advantage of this, metal tungsten is widely used for metal components such as aluminum die-castings or for hot-forging jigs and welding jigs. Otherwise, metal tungsten is most suitable for places where the metal tungsten is exposed to high temperatures for a long time. In addition to this, the metal tungsten lend themselves to manufacture of various types of heat-resistant alloys. These alloys, low in hardness like heavy metals, can be easily cut and drilled.